Successful cases

Burr Detection on Electrodes

Application Scenario

Burrs on electrodes are metal protrusions extending from the foil (non-coated area) or coated area, either upward or downward beyond the edge of the electrode. As battery separators become thinner, these burrs can puncture the lithium-ion separator, leading to contact between the positive and negative electrodes, which can cause short circuits and directly impact battery safety. Therefore, detecting edge burrs during the die-cutting and slitting stages of lithium battery production is a crucial aspect of quality control.

Project Challenges

1. High-Speed Production: Lithium electrode production lines typically run at speeds of 120m/min, with some reaching up to 150m/min. Burr defect detection requires precision levels of 10μm/pixel, and up to 3μm/pixel in some cases. These stringent requirements for precision and speed make high-speed online burr detection a significant challenge in the industry.

2. Production Variability: During production, lithium electrodes are subject to inevitable shifts and vibrations, meaning detection equipment must function effectively even as the sample's position changes constantly.

3. Critical Safety Concerns: Burr defects pose a significant threat to lithium battery safety. To ensure long-term safety, these defects must be minimized as much as possible. The detection system must conduct comprehensive inspections of the product, generating large amounts of data, which puts considerable computational pressure on image analysis.

I-TEK Solution: Burr Detection Unit

The I-TEK Burr Detection Unit enables high-speed real-time focus tracking, matching electrode movement speeds of up to 150m/min with a precision of 2.25μm. It integrates dynamic ROI, auto-focus, image analysis, and image storage functions, facilitating online high-speed detection and identification of burr defects. This significantly enhances defect detection speed and functionality integration.

Application Performance

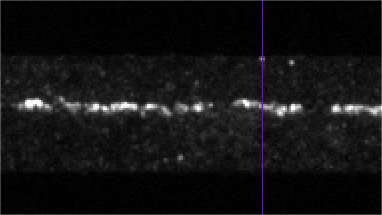

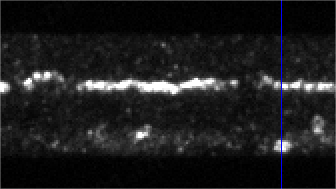

Protruding Coating

Within 3 Pixels of Coating

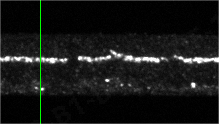

3-5 Pixels from Coating